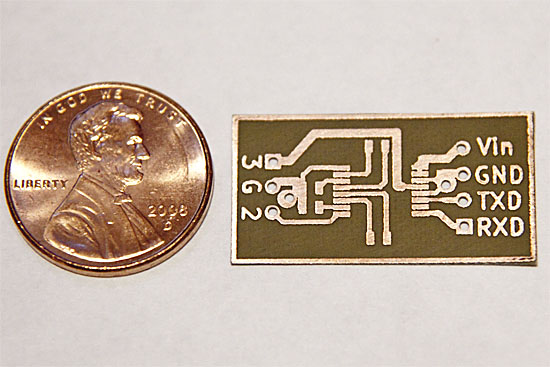

I had James etch the PCB for me since he’s set up a bit better for it thanks to a previously broken laminator I found somewhere. To produce the board he used a laser printer to print on magazine paper, then he puts the printed surface facing a clean PCB and runs it back and forth through the laminator a couple of times. Then he etches it. He has a custom acrylic tank he made that has a fish tank bubbler and heater in it. As you can see, the result is outstanding! I’m waiting for my new Hakko 936 before I attempt to solder it up however.

If you like the content on this site, please support it by using this link to order from Amazon. You know you were going to go there and buy stuff anyhow so why not help me pay the hosting bill.

How did it work out in the end? all working well?

Still trying to work it out. I have a couple of known working serial level converter boards that I will jumper the Zipit to and see if my board has an issue or the Zipit itself. I’ll be blogging more about the whole process shortly.