I had a SU700 briefly a couple of years ago but I sold it off because I didn’t really understand the workflow. It had been described to me as a hardware version of Acid but that description is not particularly accurate. I’ve been on a music kick lately though and came across this sampler again in my research. I decided to buy another one and give it another shot.

I had a SU700 briefly a couple of years ago but I sold it off because I didn’t really understand the workflow. It had been described to me as a hardware version of Acid but that description is not particularly accurate. I’ve been on a music kick lately though and came across this sampler again in my research. I decided to buy another one and give it another shot.

I found this particular SU700 on eBay for $50. It was in pretty bad shape. All of the knobs were missing and most of the encoders were shot. Someone had long since given up on this poor sampler. It was sold to a pawn shop, then I think they sold it and it was likely brought back to them because it was defective. I’m still curious when the knobs disappeared though.

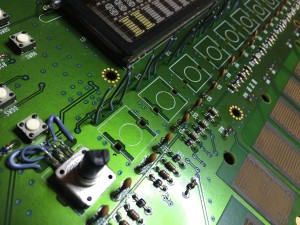

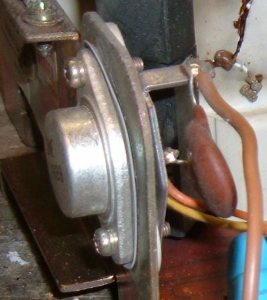

Finding new drop in replacement encoders is difficult and expensive so I researched for some alternatives. I ran across this page http://www.albates.com/yamaha-su700-encoder-repair-and-replacement/. He lists 3 recommended alternatives. I ended up going with the EC12E24404A8. I had to bend the leads straight out and wire up small jumper wires on each encoder to make it work but I’ve been very pleased with the result.

Next, now that it was working again, it was time for some new knobs. They were all missing. At first I printed some generic black knobs I found on thingiverse but they fit kind of loose for my taste and they weren’t quite what I was looking for. I ended up designing my own from scratch. What you see in the pictures is the 7th revision on the small knobs and the 2nd revision on the larger knobs on the two volume controls.

Here’s a link to the small SU700 knobs https://www.thingiverse.com/thing:1626229

Here’s a link to the larger volume knobs https://www.thingiverse.com/thing:1627286

Aside from the knobs, there was one of the matrix button covers missing. Someone on eBay is selling one for $9 +$7 shipping. This seemed a bit steep to me so I designed my own. It three revisions to get it right. It’s not rounded on top like the stock ones but it does the same job and looks close enough for me.

Here’s a link to the matrix button cap https://www.thingiverse.com/thing:1627287

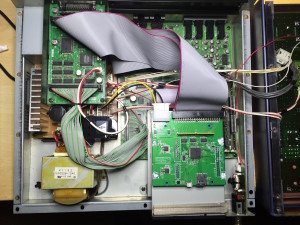

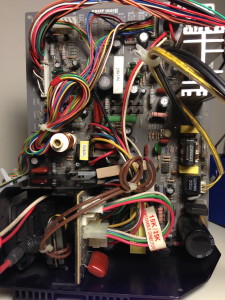

Finally, it was time for a SCSI board. The floppies work fine but in the end swapping 5-6 floppies for a song is tedious. SCSI boards are uncommonly found on eBay and they are usually $150. I found an A3000 sampler on Shopgoodwill and managed to get it for $95. All A3000’s (unless it’s already been pilfered) have the exact SCSI board that is required for the SU700. I pulled it out and then put the sampler on eBay for $100.

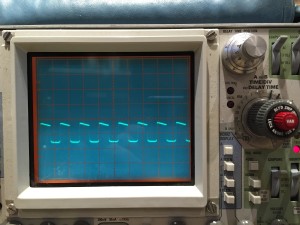

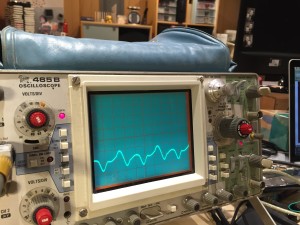

I did not want an external SCSI drive that would be loud, large, and require a separate power supply so I ended up building an SD2SCSI card for it. I was very pleased when I was first able to format the card. I put 2 partitions of 1gb each on a 4gb microSD card. Even one of these partitions should last for ages.