I knew it wouldn’t be long until another weird arcade issue surfaced. This is one that has been troubling me since I worked on this machine. The Airlock picked up a non-functioning Asteroids for fairly cheap a short while back. Round one of fixing led James (with not much help from me) to bad ram chips. Once he popped those in, the machine seemed to work until a week later when it didn’t.

During that entire week, the machine was left on freeplay as are most of the newest games when they first come into The Airlock while they are still in the functional testing phase. The game died and so I took the board home and laid a mile of solder on it to fix all the questionable joints. I also cleaned up and reseated a bunch of shaky looking roms in nasty wiper sockets.

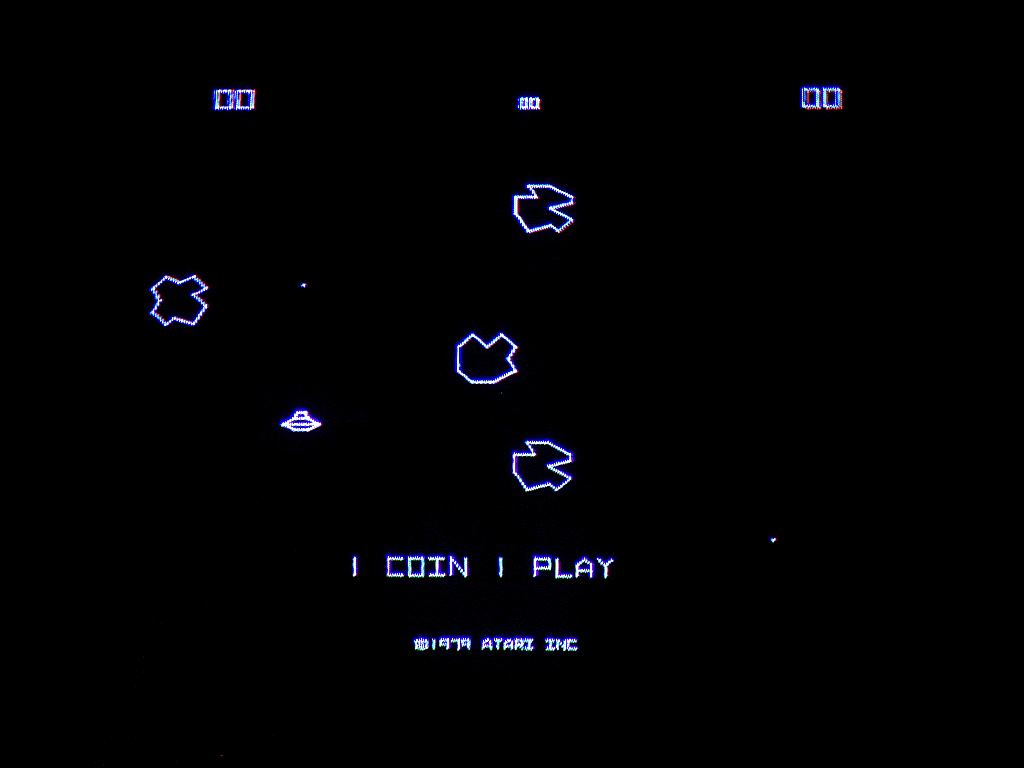

When I popped the board back it, after a little bit of finagling, it fired right up… in German. Not a problem, we tweaked up the dip switches and it was good to go. We didn’t notice the latest problem until we tried to switch it off of freeplay mode. Flipping the switch made the screen change to “1 coin, 1 play”. Problem is that when you put in a coin, then play a game, after the game is over, both start lights are flashing as if there are credits on the machine. Because there are.

We’ve had other bigger priorities to deal with so this was back burnered but I was out there tonight and by pure fluke, my dad called me. I tend to pace around when I talk on the phone so I paced and walked by Asteroids and hit several of the buttons. No one had played the game today because The Airlock was closed for a private party who was there only for Battletech. After I hit the buttons, I noticed that the credit lights were now flashing. Very curious.

I expect that the problem is that something is cross-wired in the coin door/control harness. For instance, something may not be grounded properly or what someone thought was a ground is actually another control line and they have tied it together. Kelly suspects that there is probably a short circuit on the logic board itself. Maybe I got too carried away with fixing those solder joints? Who knows. When we figure it out, I’ll post our discoveries.